Safe conveyor technology for food processing

Machine filling and line integration are an important component of food processing. Efficient production processes require reliable conveyor systems, thus pizza, pretzels, and schnitzel can be transported safely and within the shortest time possible.

That’s why our conveyor systems take products through the machine or production line with great care in a gentle and hygienic way, without damaging them. Our innovative and highly efficient conveyor systems are also convenient to use and require extremely low maintenance.

Upon request, we’d be happy to prepare special solutions just for you!

Conveyor technology for standardization

Conveyor technology for convenience

Conveyor technology for standardization

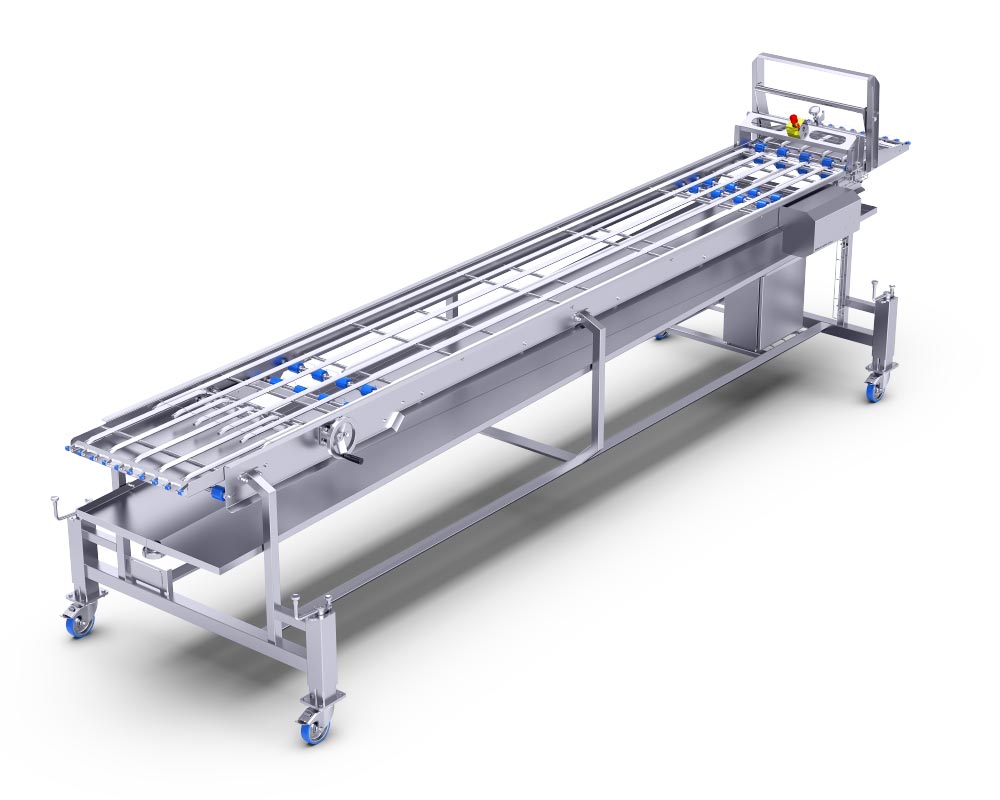

Troughed Conveyor

This conveyor technology will transport your products through the entire production process in a safe and hygienic way. The open tubular frame is easy to clean, and the rubberized drum motor can adjust the belt speed according to your needs by means of frequency control. The stable U-frame also makes it possible to change the strap quickly and without a lot of effort. All materials are made of non-corrosive stainless steel and food-approved plastic.

- Easier cleaning thanks to opened belt system with central tube

- Very effective belt scrapper

- Easy installation of belt without any tools

- Cleaning nozzles optionally available

Buffer Funnel

Our electrically controllable buffer funnel serves as a feed funnel with a dosing spiral and is positioned under the mixer outlet.

- Spiral drainage with drainage spouts allows for optimized transfer on the conveyor belt

- Spiral speed infinitely variable

- Safety circuit

- Safety guard above the free funnel area made of wire mesh

- Motor cover made of stainless steel

Screw Conveyor

Our transverse conveyor system with an optional distribution device can directly service two machines through an adjusted transport belt or a conveyor spiral in a tight space. Thanks to the pivotable product discharge with separate drive and rollers, the transverse conveyor system can fill the downstream machine according to the setting angle.

- All bearings (stainless-steel) with distance to product-related seals

- Screw trough protective guard with security prompt

- Hygienic design

- Cleaning discharge at the very bottom

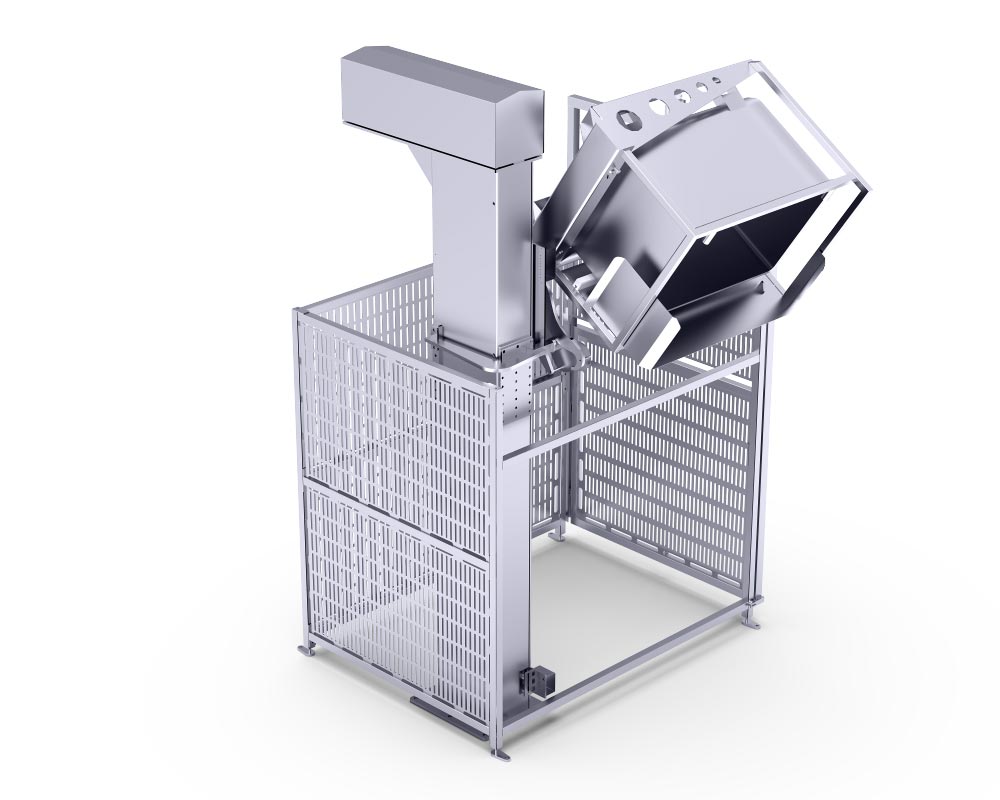

Lifting and Tilting Device

Our lifting and tilting device empties up to 600 liter boxes.

- Stationary lifting and tilting device in 2-column form, for heavy-duty operation

- Incl. drop grid and 3-sided safety grid with safety queries

- Frame made of non-corrosive stainless steel

- Emptying height of up to 5,000 mm

- Lifting capacity of 900 - 1,500 kg (depending on the design)

Conveyor technology for convenience

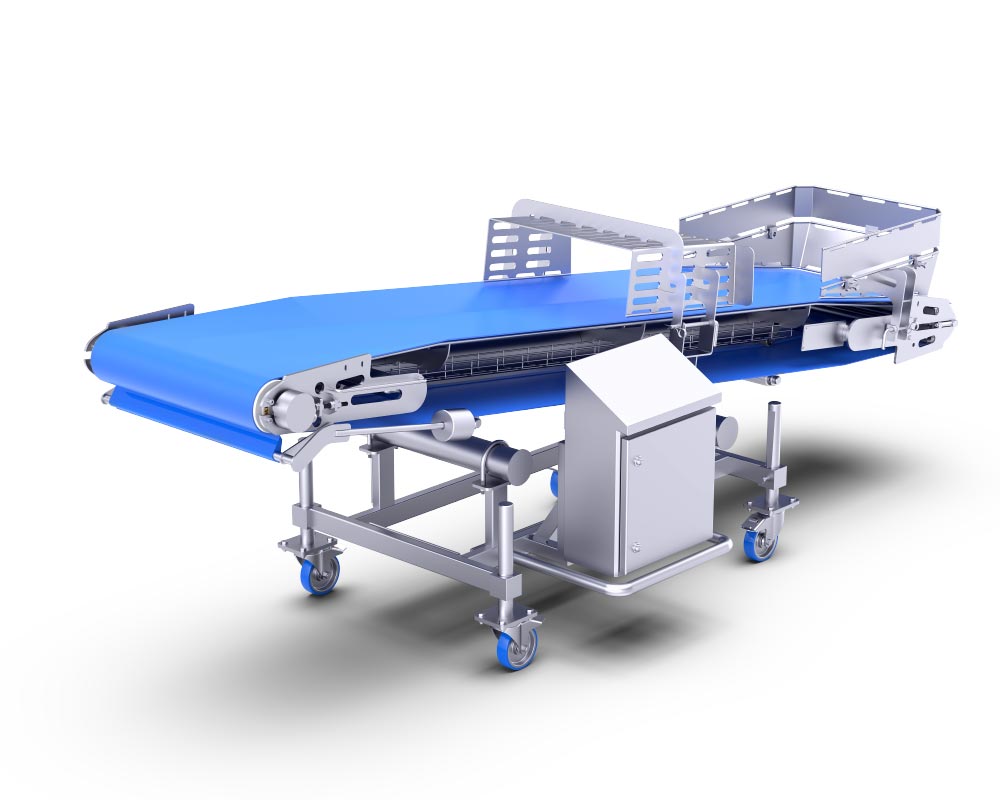

Conveyor

Our conveyors will allow for efficient and safe transport of your products through the entire production process. They’ll optimally link the individual machines to an automated line, meeting the stringent requirements for hygiene, flexibility, individuality, and safety.

- Belt speed of the strap system continuously adjustable

- Belt facings with plastic slide profiles

- Drives made of stainless steel

- Collection tray with drain opening underneath the strap system

- Designed according to the latest hygiene and safety standards

Shuttle Conveyor

The shuttle conveyor helps to efficiently and safely transfer your products onto a different line with different width, whereby both lines are set up in a rectangular configuration:

- Shuttle area and retracting speed adjustable

- Belt speed of the strap system continuously adjustable

- Belt facings with plastic slide profiles

- Drives made of stainless steel

- Designed according to the latest hygiene and safety standards

Curve Conveyor

The curve conveyor will give you more freedom in laying out your plants and provides the same advantages as our straight conveyor:

- Belt speed of the strap system continuously adjustable

- Belt facings with plastic slide profiles

- Drives made of stainless steel

- Collection tray with drain opening underneath the strap system

- Designed according to the latest hygiene and safety standards

Spiral Conveyor

The spiral conveyor serves as a connection link between two plants in order to bridge differences in height within limited production areas:

- Depending on equipment, it can also be used for pre-cooling and subsequent cooking

- Drum drive coupled directly

- All drives are treated with corrosion-resistant coating

- PLC control

- Designed according to the latest hygiene and safety standards

Got any questions? We’d be happy to personally advise you!

You can get more information on our conveyor technology and our food processing machines right from our team. We’d be happy to help you out in making plans, a purchase decision, and maintenance arrangements for your machine.