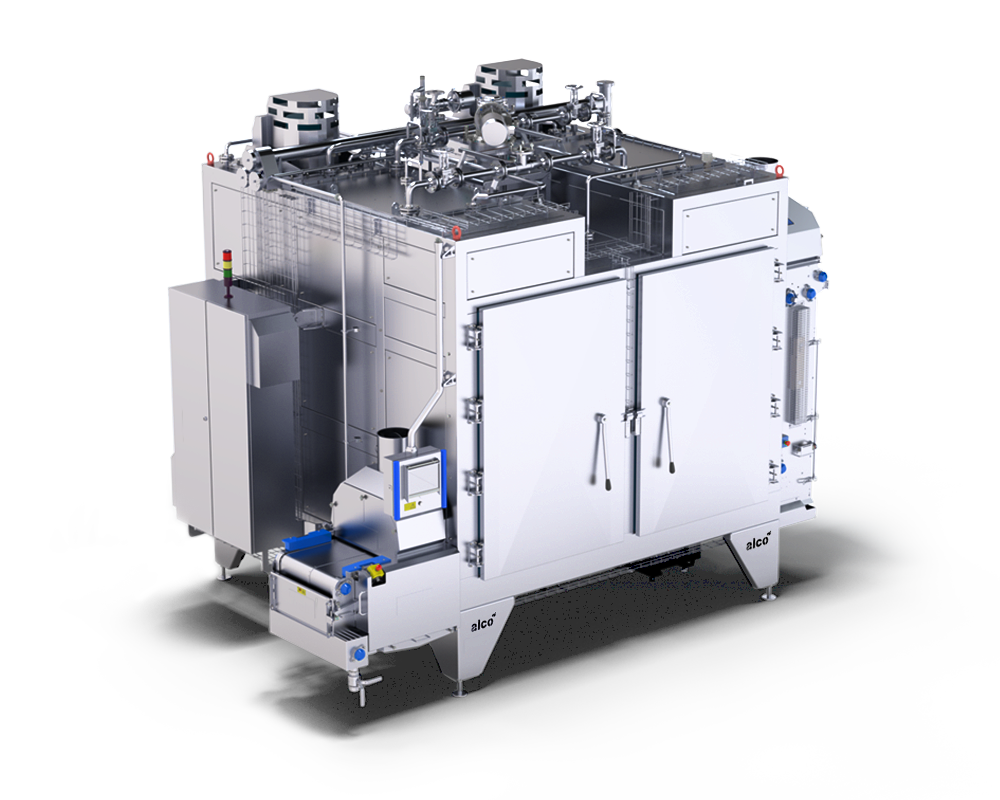

The Proofer ASG: Continuously proofed

With our proofer, you can make pizza dough, yeast-risen pastries, or lye sticks exactly following your wishes. Once your food is evenly and gently processed with the right temperature and air supply, it will stand out in terms of quality thanks to our convenience technology.

Function

The proofer from JBT ALCO will process your products consistently, gently, and quickly. It will also take up little space thanks to the spiral technology. Each machine will be tuned specifically to your production process and can be designed with flexibility according to your requirements for the number of levels.

The efficient features of our individual plant include a targeted air supply and adjustable temperature control.

Features

Our proofer is best suited for continuous proofing of various dough products.

Details

- Continuously adjustable production speed

- Suitability for products of various sizes thanks to a selectable gap between the individual levels of the spiral

- Gentle, uniform, and quick heating guarantees minimal weight loss and first-class structure preservation

- Optionally heated with steam and/or electrically

- Targeted air supply in the machine to guarantee better and uniform heat transfer

- Process temperature continuously adjustable

- Infinitely variable ventilators

- Steam injection bars for setting the desired humidity

- Combination of multiple spirals in one machine possible

- Automatic, continuous belt washing system in combination with CIP nozzles in the interior of the proofer ensure perfect cleaning

- Intuitive operation through a touch panel with recipe management

- Linked with the remote maintenance service

- Made entirely of stainless steel and food-approved plastic

- High operating safety

Our proofer

1: Evaporator/heat exchanger

can be adjusted to all common refrigerants and equipment types.

Optional

2: Fully sealed insulation cell

provides increased tightness and no maintenance joints (compared to numerous individual panels).

3: Humidifier systems

optimally humidify rooms according to product and use through steam humidification, ultrasound humidification, or high-pressure humidification.

4: Frequency converter

continuously sets the speed of the ventilators for special air speed requirements.

5: Individual product conveyor belts

allow for ideal conveying of your products according to the product requirements with various machines and surfaces.

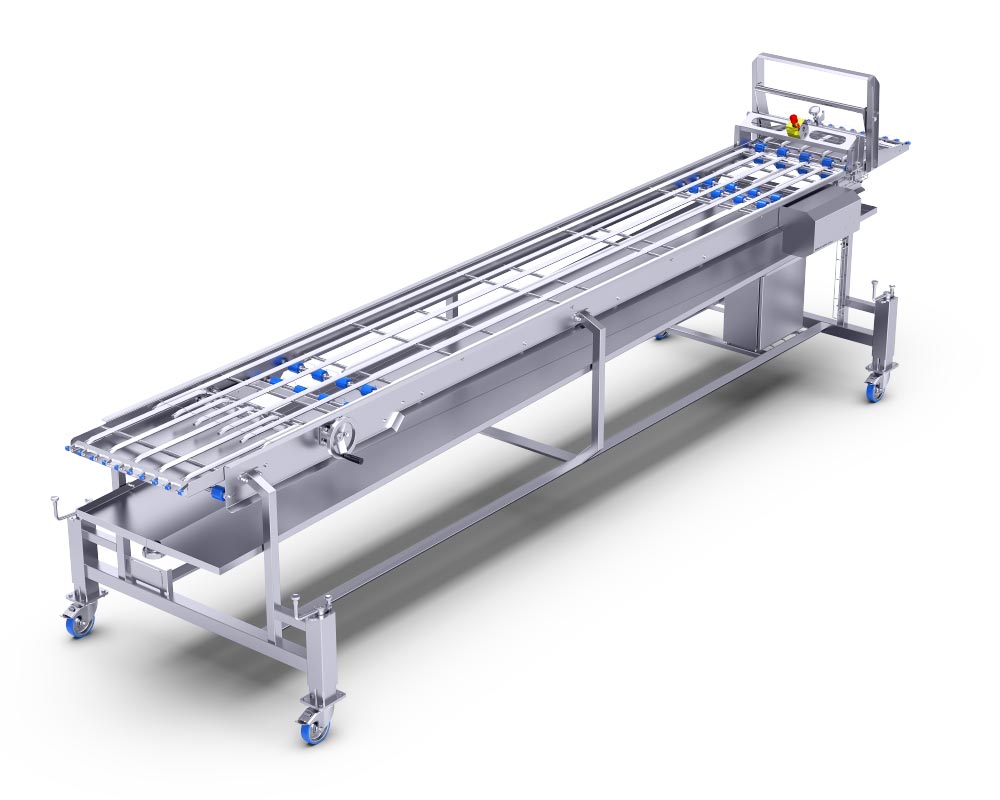

Conveyor technology

Even in front of and behind our proofer, you can count on our reliable technology. Our conveyor technology ensures optimal line integration and convenient filling. From different conveyor belts for all requirements to spiral conveyors and lifting and tilting devices to special solutions made just for you, we’ve got the right accessories for your food processing machines.

Got any questions? We’d be happy to personally advise you!

You can get more information on the proofer and our food processing machines right from our team. We’d be happy to help you out in making plans, a purchase decision, and maintenance arrangements for your machine.