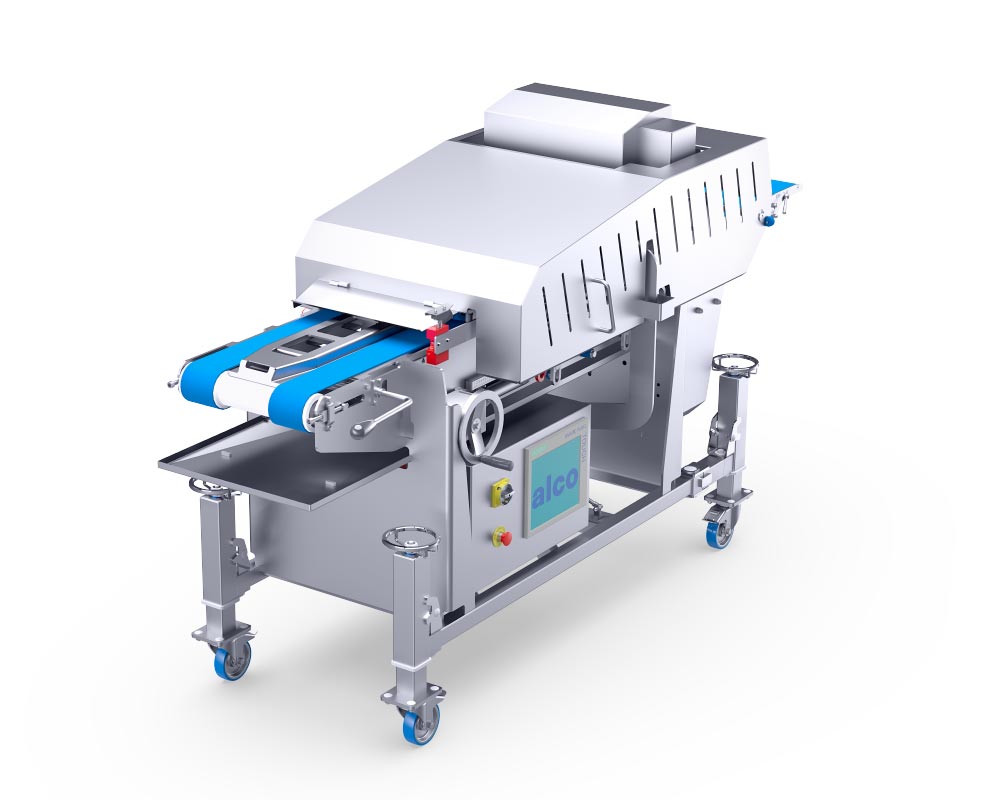

The Flattening Machine ASP: Thickness matters

Our flattening machine will give your product ideal, homogeneous product thickness. This in turn will shorten the cooking process. As a manufacturer of machines for the food industry, we know what’s important for schnitzel, poultry kebap, roulades, and poultry breast.

Function

A perfectly flattened schnitzel is characterized by an enlarged surface and standardized, homogeneous product thickness. Our flattening machine guarantees just that! Fresh and frozen products also keep their succulence in the subsequent cooking process thanks to our flattener. Schnitzel, gyros, etc. are run over an upper and lower belt through the flattening area, where a number of roller pairs press and stretch the meat in turns. The desired product thickness can be defined in advance by hand through a height adjustment.

Features

Our flattening machine flattens and rolls fresh and frozen meat. Its special feature is that it guarantees the individually set product thickness in narrow tolerances for all suitable products with low memory effect.

Details

- Continuously adjustable production speed

- Flattening area with a number of roller pairs for gentle and permanent flattening

- Height adjustment through a handwheel for setting the desired product thickness

- Perfect product transfer through a pivotable outlet belt

- Rubberized drive rollers prevent belt slipping

- Water spray bar for preventing protein build up on the belt

- Belt tensioning without tools due to easy to use thightening system

- Collection tray for product residues and clean floor policy

- High operating safety

- Belts with different profiles for various product types available

- Can be driven on four heavy-load steering rollers and rotated 360°, with parking brake and height adjustment

Our flattening machine

1: Belt adjustment

subtly adjusts the product thickness after flattening; through adjustment of the height of the upper belt by means of a handwheel and without the use of tools.

2: Outlet hold-down belt

optimally transfers the product to the subsequent equipment.

Optional

3: Special belts

optimally adjust to the product through various belts.

4: Extended infeed area

additional space in infeed area to put products down.

5: Spindle height adjustment

sets the height of the entire machine by means of a handwheel.

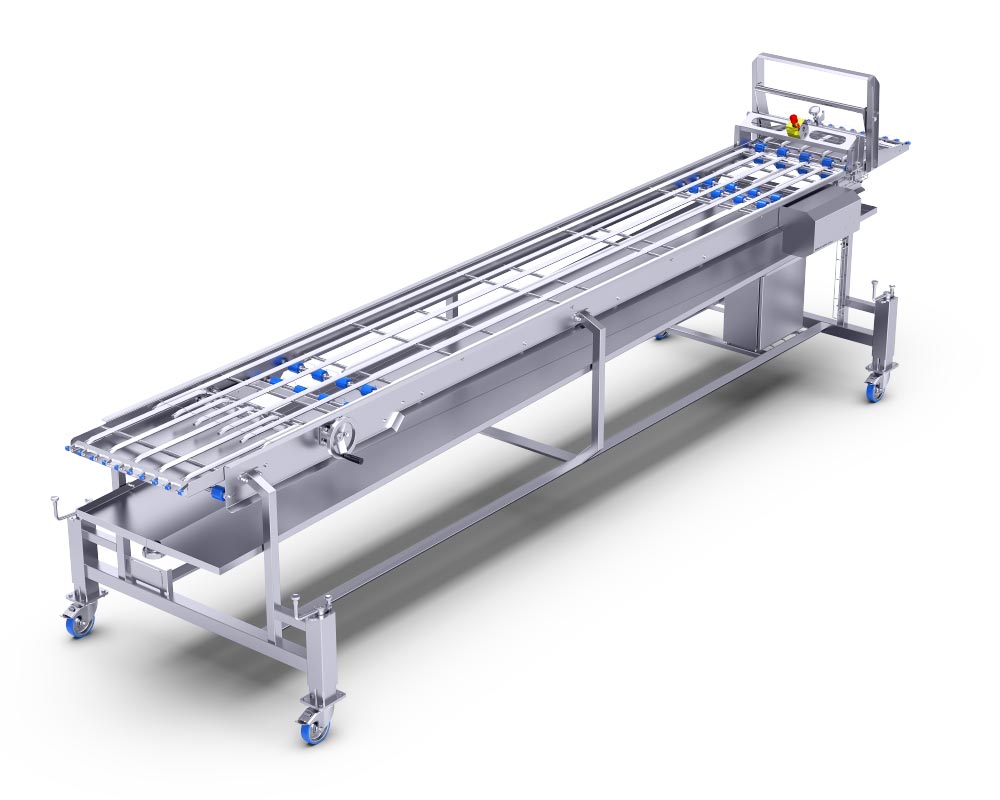

Conveyor technology

Even in front of and behind our flattening machine, you can count on our reliable technology. Our conveyor technology ensures optimal line integration and convenient filling. From different conveyor belts for all requirements to spiral conveyors and lifting and tilting devices to special solutions made just for you, we’ve got the right accessories for your food processing machines.

Got any questions? We’d be happy to personally advise you!

You can get more information on the flattening machine and our food processing equipment right from our team. We’d be happy to help you out in making plans, a purchase decision, and maintenance arrangements for your machine.