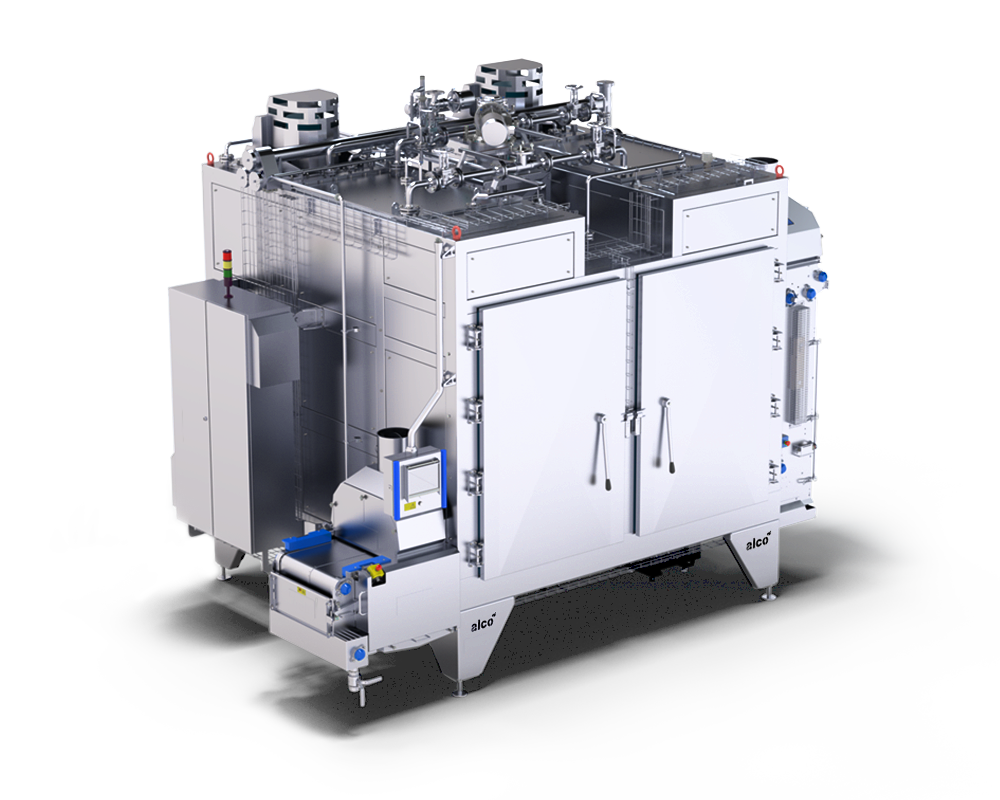

The Linear Convection Oven AGU: Well-Tempered

The linear convection oven has two heating areas available that can be tempered differently at the same time. That’ll bring you maximum efficiency in food processing with minimized energy consumption.

Function

With its dual-area system, our linear convection oven stands for maximum efficiency. Two separately adjustable heating areas provide the option of cooking and browning food at the same time using different temperatures. That way, the system makes perfect use of energy consumption. Different product sizes easily fit into the oven side by side, and the oven allows for consistent cooking results through hot circulating air and/or steam.

Features

Our linear convection oven heats, cooks, and browns products with circulating air and/or steam. Its special feature: Two separately adjustable heating areas guarantee optimal cooking results and minimal losses of moisture.

Details

- Continuously adjustable production speed

- Suitability for products of different sizes

- Optionally heated electrically or with thermal oil and/or steam

- Targeted airflow for guaranteeing optimal and uniform heat transfer and browning

- Air speed adjustable through ventilators

- Steam injection bars for setting the desired humidity

- Optimal dew point control for maximizing yield

- Process temperature infinitely variable up to max. 250 °C

- Automatic, continuous belt wash system in combination with CIP nozzles in the interior of the oven ensures perfect cleaning

- Intuitive operation through a touch panel with recipe management

- Linked with the remote maintenance service

- Insulated housing design for preventing energy losses

- Made entirely of stainless steel and food-approved plastic

- High operating safety

Our linear convection oven

1: Top-performance heating elements

ensure efficient heat transfer. Choice between electrical and thermal oil-powered heating elements possible in up to 2 different climate zones.

2: Belt wash system

continuously cleans the conveyor belt by means of rotating brushes and water spray lances.

3: Lecithin soak

minimizes product adhesions through simple moistening of the conveyor belt.

4: CIP

is a complete cleaning system for the interior of the linear oven.

Optional

5: Dew point control

ensures a consistent and constantly adjustable climate through a moisture measurement and control system.

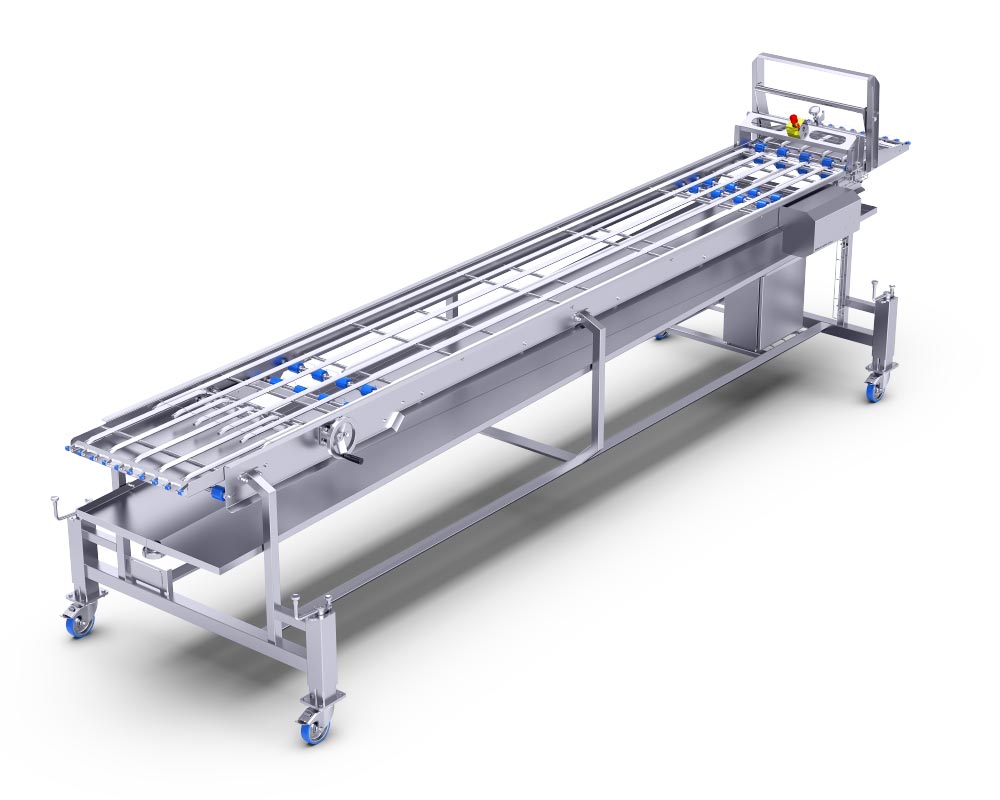

Conveyor technology

Even in front of and behind our linear convection oven, you can count on our reliable technology. Our conveyor technology ensures optimal line integration and convenient filling. From different conveyor belts for all requirements to spiral conveyors and lifting and tilting devices to special solutions made just for you, we’ve got the right accessories for your food processing machines.

Got any questions? We’d be happy to personally advise you!

You can get more information on the convection oven and our food processing machines right from our team. We’d be happy to help you out in making plans, a purchase decision, and maintenance arrangements for your machine.